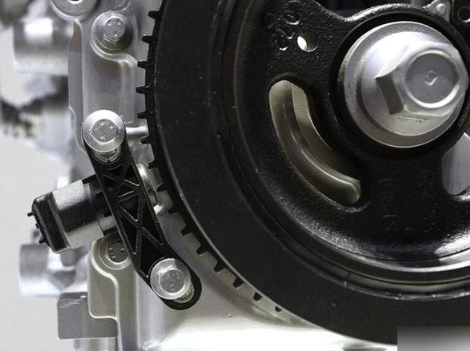

Dorman crankshaft position sensor

What will a bad crankshaft position sensor do?

A bad crankshaft position sensor can cause a variety of engine performance issues. Here are some common crankshaft sensor problems:

- Difficulty Starting the Engine: The engine may crank but struggle to start, or it might not start at all.

- Engine Stalling: The engine might suddenly stall while idling or at low speeds, which can be quite dangerous in traffic.

- Misfiring: You might experience misfires in one or more cylinders, causing rough running and loss of power.

- Check Engine Light: The check engine light will likely illuminate, indicating a problem with the sensor. Diagnostic trouble codes related to the crankshaft sensor may be stored in the ECM.

- Poor Acceleration: There might be a noticeable lag or hesitation when you try to accelerate, making the vehicle less responsive.

- Reduced Fuel Efficiency: The engine might consume more fuel than usual, leading to poor fuel economy.

- Engine Vibrations: The engine could run roughly or vibrate more than normal, indicating incorrect timing.

Since the crankshaft position sensor provides critical information about the engine’s position and rotational speed, its failure can disrupt the engine’s management system, affecting ignition timing and fuel injection. crankshaft sensor symptoms.

Can I reset my crankshaft position sensor?

You can’t reset the dorman camshaft position sensor itself, but you can reset the vehicle’s engine control module (ECM) to ensure it correctly recognizes the new sensor. This process is often referred to as a “relearn procedure.” Here’s a basic outline of what you might need to do:

Steps to Reset the Computer:

- Disconnect the Battery: – Turn off the ignition and disconnect the negative battery cable. – Wait for about 10-15 minutes to allow the ECM to reset.

- Reconnect the Battery: – Reconnect the negative battery cable.

- Start the Engine: – Start the engine and let it idle. The ECM will begin to relearn the new sensor’s position.

- Driving Cycle: – Let the engine warm up to its normal operating temperature. – Drive the vehicle at various speeds and loads. Try to include highway driving, city driving, and idling periods to provide a complete range of operating conditions.

- Check for Errors: – Use an OBD-II scanner to check for any error codes. If everything is working correctly, there should be no codes related to the crankshaft position sensor.

- Clear Codes (if necessary): – If the check engine light remains on or there are any error codes, use the OBD-II scanner to clear them.

This procedure helps the ECM properly synchronize the new sensor with the engine’s operation. If you’re unsure about the process or if the vehicle doesn’t run smoothly after the replacement, it might be a good idea to consult a professional mechanic.

What code will a bad crankshaft sensor throw?

A bad crankshaft position sensor typically triggers the P0335 diagnostic trouble code (DTC). This code indicates a malfunction in the crankshaft position sensor “A” circuit. When the engine control module (ECM) detects an issue with the sensor, it sets this code and illuminates the check engine light.