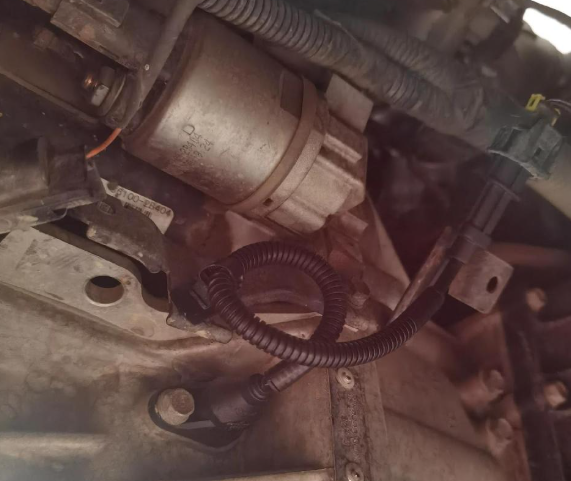

Denso camshaft position sensor

What kills a camshaft sensor?

A camshaft position sensor can fail due to several reasons, including:

- Electrical Issues: Faulty wiring, poor connections, or damaged electrical components can disrupt the sensor’s signal.

- Contamination: Dirt, oil, or debris can accumulate on the sensor, affecting its ability to function properly.

- Heat and Wear: Over time, the sensor can wear out or become damaged due to exposure to high temperatures and harsh conditions.

- Water Damage: Exposure to moisture or water can cause corrosion and damage to the sensor.

- Mechanical Damage: Physical impact or damage to the sensor or its mounting can impair its functionality.

Regular maintenance and inspections can help prevent sensor failures. If you suspect a problem with your camshaft position sensor, it’s best to have it diagnosed and replaced by a professional mechanic.

Do camshaft position sensors need to be programmed?

In most cases, camshaft position sensors do not need to be programmed. They are typically plug-and-play components. Once installed, the vehicle’s engine control module (ECM) will automatically recognize the new sensor and use its data to manage the engine’s timing and fuel injection.

However, in some vehicles, it might be necessary to perform a sensor relearn procedure using an OBD-II scanner to ensure optimal performance. This helps the ECM adjust to the new sensor and calibrate its readings accurately.

What are the symptoms of bad camshaft sensor position?

A bad camshaft position sensor can cause a variety of engine performance issues. Here are some common camshaft position sensor symptoms you might encounter:

- Difficulty Starting the Engine: The engine may crank but struggle to start, or it might not start at all.

- Engine Stalling: The engine might suddenly stall while idling or at low speeds, which can be dangerous.

- Rough Idle: The engine may idle roughly or shake more than usual.

- Check Engine Light: The check engine light will likely illuminate, indicating a problem with the sensor. Diagnostic trouble codes related to the camshaft sensor may be stored in the ECM.

- Poor Acceleration: There might be noticeable hesitation or a lack of power when you try to accelerate.

- Misfiring: The engine might misfire, causing rough running and loss of power.

- Reduced Fuel Efficiency: The engine might consume more fuel than usual, leading to poor fuel economy.

- Engine Vibrations: The engine could run roughly or vibrate more than normal.

Since the camshaft position sensor provides crucial information about the camshaft’s position and speed, its failure can disrupt the engine’s management system, affecting ignition timing and fuel injection.

How do you reset a camshaft position sensor?

Resetting a camshaft position sensor usually involves a relearn or recalibration process rather than a simple reset. Here’s a general guide on how to do it:

Steps to Relearn a Camshaft Position Sensor:

- Locate the Sensor: The camshaft position sensor is typically located near the camshaft in the engine block.

- Disconnect the Battery: Disconnect the negative battery cable to prevent any electrical issues.

- Remove the Old Sensor: Disconnect the electrical connector from the sensor and remove the bolts securing it to the engine block. camshaft position sensor replacement.

- Install the New Sensor: Lubricate the O-ring on the new sensor with a small amount of oil, insert it into the mounting hole, and secure it with the bolts.

- Reconnect the Battery: Reconnect the negative battery cable.

- Turn on the Engine: Start the engine and let it idle for a few minutes to allow the ECM to recognize the new sensor.

- Drive the Vehicle: Drive the vehicle at varying speeds (e.g., up to 55 mph) and then gradually decrease the speed until the check engine light flashes. This helps the ECM recalibrate and adjust to the new sensor.

Additional Tips:

- Use an OBD-II Scanner: Some vehicles may require a CASE relearn procedure using an advanced OBD-II scanner. Follow the scanner’s instructions for the recalibration process.

- Consult the Service Manual: Refer to your vehicle’s service manual for specific instructions and any additional steps required for your make and model.