What is a crankshaft position sensor?

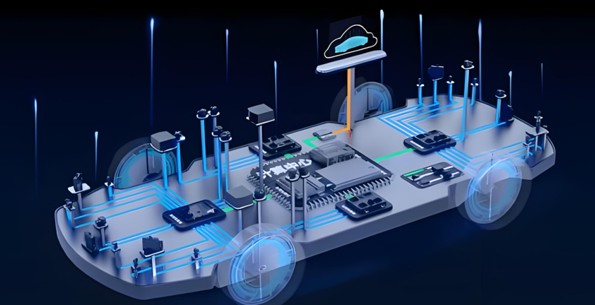

The crankshaft position sensor is one of the most important sensors in the automotive control system. It identifies the rotation direction of the crankshaft by detecting the target gear groove on the crankshaft.

The following is a detailed analysis of the crankshaft position sensor and its TDC detection function:

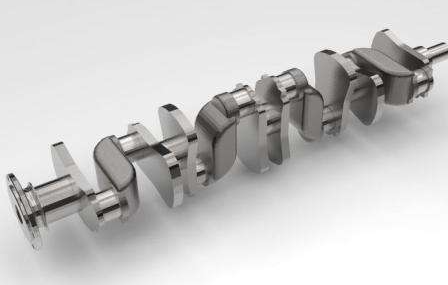

1. Crankshaft position sensor basic information

- Function: Detecting engine speed and piston TDC position is an important basis for controlling ignition and fuel injection.

- Installation location: The crankshaft position sensor location is usually mounted on the distributor, above the crankshaft gear in the crankcase.

- Working principle: Based on the magnetoresistance effect. The variable reluctance rotor inside the sensor works in conjunction with the target wheel on the crankshaft. When the crankshaft rotates, the magnetic field of the variable reluctance rotor will change accordingly, thereby inducing the sensor to generate an induced voltage pulse to achieve accurate detection of the sensor crankshaft position.

2. TDC detection function of crankshaft position sensor

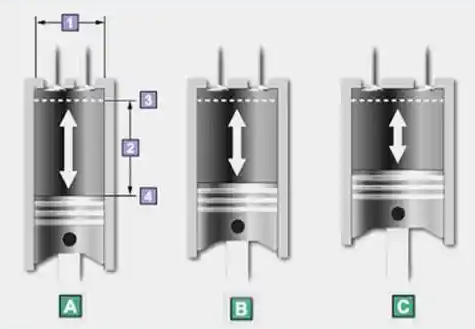

- Definition of TDC: The piston top dead center (TDC for short) refers to the point when the piston moves to its highest position in the cylinder.

- Importance of TDC detection: The TDC position of the piston is crucial to controlling the ignition timing and the amount of fuel injection. Accurately detecting the TDC position can ensure that the engine can achieve the best combustion effect under various working conditions, thereby improving the engine’s performance and fuel economy.

- TDC detection principle: The crank crankshaft position sensor determines the rotation direction and position of the crankshaft by detecting the target wheel groove on the crankshaft. When the crankshaft rotates to a certain position, that is, when the piston moves to TDC, the sensor receives a specific signal (such as an induction voltage pulse) to identify the TDC position of the piston.

3. Other functions of the crankshaft position sensor

In addition to detecting the TDC position, the crankshaft position sensor also has the following functions:

- Detecting engine speed: By calculating the speed of crankshaft rotation, the engine speed can be accurately measured. This is of great significance for controlling the working state of the engine and the amount of fuel injection.

- Capturing the TDC signal of each cylinder: The crankshaft position sensor is able to capture the TDC signal of each cylinder, including the TDC signal of the first cylinder used to control sequential fuel injection. This helps to achieve more accurate fuel injection control and ignition control.

4. Summary

The crankshaft position sensor detects the target wheel tooth groove on the crankshaft to identify the rotation direction and position of the crankshaft, thereby accurately detecting the engine speed and piston TDC position. These detection functions are essential for controlling ignition and fuel injection, helping to improve engine performance and fuel economy. Therefore, the crankshaft position sensor plays an important role in the automotive control system.