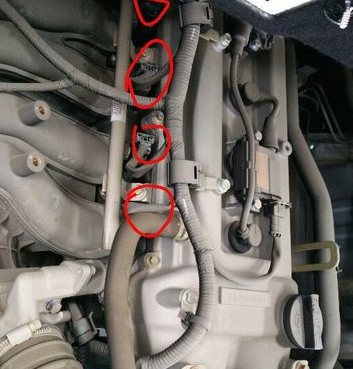

Bosch crankshaft position sensor

What are 3 top common reasons to determine when the crankshaft position sensor is failing?

Here are three common crankshaft position sensor symptoms that can indicate a failing Bosch crankshaft position sensor:

- Wheel and Pin Damage: The sensor measures magnetic pulses created by a toothed wheel or pins. If any of these teeth or pins are broken, snapped off, or worn down, it disrupts the pattern of the pulses, confusing the sensor.

- Magnetic Problems: The sensor’s magnet can attract metal shavings created by engine friction. These shavings can stick to the sensor or the wheel, throwing off the sensor’s measurements.

- Circuitry and Wiring Issues: Problems with the internal circuitry or the wires connecting the sensor to the engine control unit (ECU) can cause failures. A short circuit or an open circuit in the sensor can prevent it from giving accurate readings to the ECU.

Does a crankshaft sensor have to be programmed?

In most cases, a crankshaft position sensor does not need to be programmed after installation. It’s a plug-and-play component designed to provide real-time data to the engine control unit (ECU) without any additional programming. However, after replacing the sensor, it’s a good practice to clear any error codes from the ECU and perform a system reset to ensure everything is working correctly.

How much does it cost to replace a crankshaft sensor on a BMW?

The cost to replace a BMW 325I E36 crankshaft position sensor replacement can vary depending on the model, year, and location. On average, you can expect to pay between $150 and $400 for the replacement. This includes both parts and labor costs.