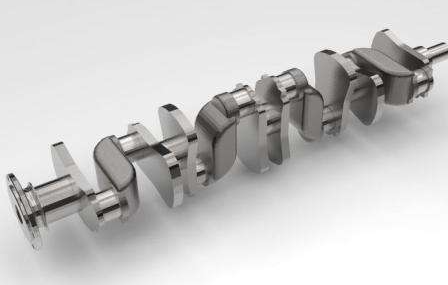

Denso Crankshaft Position Sensor

Denso is a reputable manufacturer of crankshaft position sensors, known for their quality and reliability. Their sensors are designed to provide accurate monitoring of the crankshaft’s position, ensuring optimal engine performance and efficiency. Denso offers two main types of crankshaft position sensors:

- Magnetic Resistant Element (MRE) Type: These sensors are highly accurate and durable, with a design that integrates the detection element and processing circuit on one chip.

- Magnetic Pick-Up (MPU) Type: These sensors are widely used and known for their precision and reliability.

Can you drive a car with a bad crankshaft sensor?

While a car with a bad crankshaft position sensor can technically still be driven, it is generally not recommended.

What are the symptoms of a faulty crankshaft position sensor?

Crank sensor problem: A faulty crank position sensor can cause a range of issues in your vehicle. Here are some common crankshaft position sensor symptoms:

- Check Engine Light: One of the most immediate signs is the illumination of the check engine light on your dashboard.

- Difficulty Starting: The engine may have trouble starting or may not start at all.

- Engine Stalling: Your engine might stall unexpectedly, either at idle or while driving.

- Reduced Engine Performance: You might notice poor acceleration, reduced power, and increased fuel consumption.

- Rough Idling: The engine may idle inconsistently or roughly.

- Misfires and Vibrations: Engine misfires can lead to rough running and excessive vibrations.

- Erratic Timing: The engine’s timing can become erratic, affecting overall performance.

- Poor Fuel Economy: Inefficient fuel combustion due to improper timing can lead to decreased fuel efficiency.

How do you reset a crankshaft position sensor?

To reset a crankshaft position sensor, you typically need an OBD-II scanner or diagnostic tool. However, if you don’t have one, here’s a method you can try to reset the sensor manually:

Method 1: Disconnecting the Battery

- Turn off the ignition: Ensure the vehicle is off and parked in a safe location.

- Locate the battery: Open the hood and find the battery.

- Disconnect the negative terminal: Use a wrench to loosen and remove the negative battery terminal (usually black).

- Wait for about 15 minutes: Allow the engine control unit (ECU) to reset.

- Reconnect the battery: Reattach the negative battery terminal and tighten it securely.

- Start the vehicle: Turn on the ignition and check if the issue is resolved.

Method 2: Using a Diagnostic Tool (Preferred Method)

- Connect the Scanner: Plug the OBD-II scanner into the diagnostic port of your vehicle.

- Enter the Menu: Navigate to the appropriate menu for resetting the crankshaft position sensor.

- Select Adaptation Reset: Look for an option related to adaptation or sensor adaptation reset.

- Follow Instructions: Follow the on-screen prompts to complete the reset process.