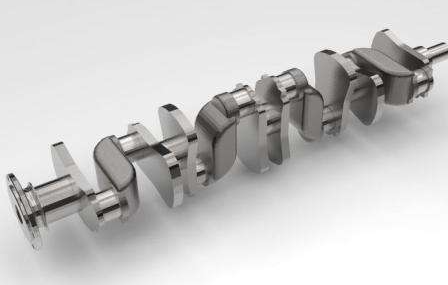

Mopar Crankshaft Position Sensor

What is Mopar crankshaft position sensor?

Mopar, the official parts brand of Chrysler, offers a variety of crankshaft position sensor Mopar for different models and years. Here are a few examples:

- Mopar Sensor-Crankshaft Position (Part No. 56027870): Suitable for Dodge Dakota, Dodge Durango, and Dodge Ram models from 1997-2003.

- Mopar Crankshaft Position Sensor (Part No. 05033307AE): Designed for various models from 2005-2020, including Dodge Journey, Jeep Compass, and Jeep Patriot – Mopar Estores.

- Mopar Genuine Crankshaft Position Sensor (Part No. 5149167AF): Available for specific models like the Dodge Journey and Jeep Compass. 1998 jeep cherokee mopar crankshaft position sensor. 1999 jeep cherokee mopar crankshaft position sensor.

What happens when your crankshaft sensor goes bad?

When a crankshaft position sensor goes bad, it can lead to various issues in your vehicle’s performance. Here are some common crankshaft position sensor symptoms:

- Engine Misfires: The engine may misfire or run rough because the sensor is not providing accurate data to the engine control unit (ECU).

- Stalling: The engine might stall unexpectedly, which can happen both at idle and while driving.

- Starting Problems: The vehicle may have trouble starting, or it might take longer than usual to start.

- Check Engine Light: The “Check Engine” light on your dashboard will likely illuminate.

- Poor Acceleration: You might notice a lack of power or poor acceleration.

- Rough Idling: The engine may idle inconsistently or roughly.

- Reduced Fuel Efficiency: The engine may consume more fuel than usual due to improper timing and fuel mixture.

These issues occur because the crankshaft position sensor provides crucial information about the crankshaft’s position and speed to the ECU, which uses this data to control ignition timing and fuel injection. A faulty sensor disrupts this process, leading to the symptoms mentioned above.

Is a crank sensor hard to replace?

Replacing a crankshaft position sensor can vary in difficulty depending on the make and model of your vehicle. Here’s a general overview to help you decide:

General Steps:

Disconnect the Battery: To ensure safety, always disconnect the negative terminal of the battery.

Locate the Sensor: Refer to your vehicle’s service manual to find the exact location of the crankshaft position sensor.

Remove Obstructions: If needed, remove any components obstructing access to the sensor.

Disconnect the Sensor: Unplug the electrical connector from the sensor.

Remove the Sensor: Use the appropriate tools to remove the mounting bolt(s) and carefully extract the sensor.

Install the New Sensor: Position the new sensor, secure it with the mounting bolt(s), and reconnect the electrical connector.

Reconnect the Battery: Reattach the negative terminal of the battery.

Clear Error Codes: If you have an OBD-II scanner, clear any stored error codes and verify that the new sensor is functioning properly.